Additive technologies arose in 1983 – much earlier, than people started using a world wide web in large quantities. But Internet became for a long time an ordinary part of the life, and still it is impossible to call Additive technologies Charles Khall believes that we already passed the period haypa and just now we start understanding the real field of application of technologies. This post how Charles Khall (Charles) Charles Khall invented and patented laser stereolithograph in a small subsidiary room and how it now estimates the invention.

Spoiler: as well as Industrial robot , to development Additive technologies strongly were helped by automotive industry. and prototyping

Everything began

of the Table-top in the 80th. Then Charles Khall worked as the technologist in the Californian Ultra Violet Products. Company made pitch of an ultra-violet otverzhdeniye for table-tops. About the high speed of work could not go and speeches — on development and testing even small details were required months. Charles Khall as production responsible for the organization entered duties also prototyping. The inventor looked for a method which would allow it to accelerate process.

of One of his ideas was to impose some hundred layers of plastic and to give them a certain form by means of an ultraviolet. So rather cheap and fast prototype in creation would turn out. With this idea it went to UVP management. to Charles Khall, of course, did not allow to be engaged in the invention in working hours – but allocated the room and the equipment.

a year of overtime work Later the inventor created the first prototype electrolytic 3D - the printer. It worked with photopolymer – substance which can pass from a liquid state in firm under the influence of ultra-violet beams. Charles Khall learned to write a code to program the printer on creation of a prototype of a certain geometrical figure. The small plastic glass became the first 3D-printing object.

First 3D - the SLA-1

"Put on and come to laboratory right now"

Night when discovery was made, forever imprinted in memory of the wife Charles Khall – Khall Antoinette. In interview for newspaper "The Daily Telegraph" it even calls exact time – 20:39 on Wednesday, March 9, 1983. "That night I was at home

, and I had to look for hours when phone" rang out, – she told. "I already was in a pajamas and prepared for a dream, but Charles Khall still worked".

"Put on and come to laboratory right now", – Chuck told by phone Charles Khall for researches.

B to it Khall Antoinette saw the first 3D-printing object in the world. "Holding this strange detail in hand, he told that made it and the world never will be former. That night I knew that it reached something grandiose".

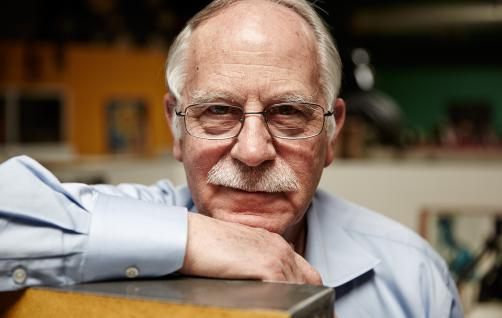

Charles Khall with the wife

At companies where Charles Khall worked, was not means for financings development. He remembers: "I took out the patent on 3D - the printer in the 86th year. And here I come to the head of companies and I speak: "We need to find for it commercial application". On what he answers: "Certainly, but we cannot afford it". I had no choice therefore I decided to create the own company. It also became the beginning 3D Systems". The first clients of its companies became General Motors Co. and Mercedes-Benz.

the Company works still. Charles Khall, to which now 79 years, too. "My work is too interesting to give up it", – he told somehow in interview for TV channel "CNN". In other he reported more details: "In the late nineties I really retired. The new head came to my place, and somewhere three months later he called me and told: "Charles Khall, everything is bad. You can return and help with the solution of some technical problems? " Since then I again there, continue to be engaged in interesting things".

Now the 3D Systems sosredotochena on programmable systems for molding under pressure which will allow to print objects without preliminary designing of forms. Besides work in 3D Systems, Charles Khall gives lectures and speaks at conferences. For example, he became one of the chief speakers on last year's ASME – the international congress of mechanical engineering.

Charles Khall remains very modest person. In 2014 the European patent department awarded to it a prize as to the best inventor working outside Europe. He answered it only: "It is pleasant to me to gain recognition of my merits. I much and persistently worked, than I and am going to be engaged further".

it communicates With mass media seldom. Below – one of its few interviews, this Industry Week . It 2013, but completely was not translated into Russian. In it Charles Khall told how itself long did not believe in commercial success of the invention and about, whether it will be able sometime to compete with traditional production.

you invented stereolithograph in the 1983rd. 30 years later the market The 3D - technologies started growing roughly. It seems to people that this any new phenomenon. What do you think concerning this boom? Whether late it began? When we only started being engaged in

Additive technologies, I long could not present that it becomes so popular.

seemed to me, this way will borrow years 25 if it is no more. Such is history of all inventions. Does not happen such that you invented a thing like 3D - the printer, and the crowd of buyers started breaking at once your door. A lot of time is necessary to understand that you invented and as it can be improved.

Additive technologies — it is difficult. You see the ready device. Think that very easily to use it, but it not so. We in the 3D Systems improved the first printer for 10 years. During this time it was succeeded to pass a way from idea to an embodiment of the ready device in the industrial sphere.

But the last some years surprised me. That people recognized Additive technologies as the widespread direction, certainly, became a surprise.

When you had an idea to create Additive technologies? How you thought up a stereolithograph method?

Ya began as the design engineer. Development of new molding details from plastic in which we were engaged, was very labor-intensive and expensive process. In the beginning you developed appearance of a detail, did drawings, discussed everything with the toolmaker who did a form for plastic part. Then this form went to the founder who made the spare part. All process took 6-8 weeks.

Production took a lot of time, besides the first turned-out detail never was ideal. It should be remade and again to start a production cycle . Many months passed before you received a detail which can be tested.

is natural, we tried to make something with it.

Ya decided to check, whether I will be able to think up a way quicker to receive this first detail that all repeated cycles passed quickly, and then quickly to receive the final version for productions.

Ya touched a heap of ideas which did not work, and then came to that as a result became stereolithograph. On March 9, 1983 I made this method the first detail.Then you submitted to

the patent application, received in the 1986th and became the co-founder 3D Systems. But who was your clients? Any of the industries saw potential at so early stage?

When we only started company, at once sent "scouts" – to understand, whether there is an interest from the industry. And it was. Actually, interest to prototyping was huge, generally from autoconcerns.

of the Autocompany at that time tried to release quality cars. The American concerns were at that time quite slow. They could not let out quickly new models, and quality of productions lost in the world competition.

Therefore they had a huge interest in any technologies which could improve a situation. We began to move at once in this direction, to develop technology for automotive industry. Soon after that a great number of producers went on the same way.

Also those years we developed methods of prototyping of metal details. Ours technology had to offer alternative to traditional molding by a method of the lost wax, and it was the first serious branch from prototyping of plastic details. the Developed method we called by

Quick Cast. He allowed to pour quickly metal details from various alloys, and him still use. Mainly in space and branches adjacent to it.

Now when producers and buyers realized all value Additive technologies, what will be farther? Whether it will be able sometime to compete with traditional production?

Ya not the futurist and at me is not present a crystal sphere of the predictor – I do not know that will occur further. But I know that when enough of clever people works over something, it something becomes always better.

the Main advantages of Additive technologies now — thin settings and opportunity to work with difficult designs. If in your production the set of details is necessary or details with a set of different parameters are necessary, Additive technologies can be useful to you.

Medical application — natural for Additive technologies, after all all bodies different. When you try to make something for teeth, for example, this thing will be different for different patients. The same touches knees and other joints.

If you look into the future Additive technologies, it probably of a detail with difficult forms and patterns, even at large volume of productions. Speed and economic benefit from Additive technologies constantly increase. So, at it becomes more and more chances to compete with traditional production.

Looking back on these 30 years — that you would designate the biggest achievement, disregarding technology? in the 80-90th years it was clear to

that production will gradually leave the country. It concerned not only United States of America — everything went to the countries with cheap labor. I always considered that it is bad. In my opinion, production has to be key ability, especially for United States of America. Today return to production in the territory of the country is connected with higher technological capabilities. It is pleasant to me that Additive technologies and digital production to it promote.

on October 12-13 we will hold in Moscow exhibition Additive technologies and 3D - scannings – 3D Print Expo. It becomes already the sixth.

This time we changed a format and concentrated on practice. Conference this year will not be — will be exhibition and a lecture hall. Certainly, there are master classes, gallery of 3D-printing objects and drawing 3D - handles.

of the Detail and the program look for on the official site .