In the territory Southwest China performed first-ever operation where involved technologies Additive technologies on a knee joint. To create new fabrics to the 84-year-old patient, added there a quantity of rather rare metal – tantalum. According to doctors, everything passed very well.

Sick managed to do without assistance some main movements, testing a "new" knee. Allegedly, in some days it even will write out. In the First hospital of Medical university of the province Province of Anhui often perform operations, replacing knee joints.

However, according to physicians, often there are postoperative infections and other complications therefore quite often there was a set of various defects. Thanks to individual tantalic implants for which projecting the computer design was used, it was succeeded to solve this problem after all. They became a peculiar buffer between a living tissue and artificial. Standardly tantalum apply to restoration of teeth and in surgeries, and an organism it almost never tears away. Respectively, with I will sew it it is possible "to patch" and other parts of a body, if necessary.

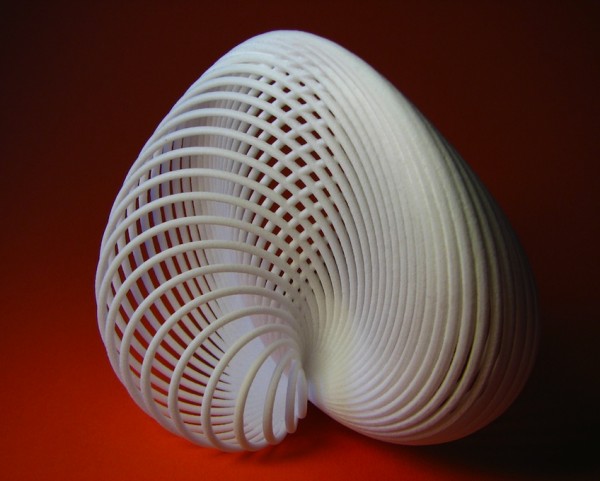

Additive technologies were thought up 34 years ago by the American inventor Charles Khall. 1999 – time when it involved in medicine to implant to the patient body which was grown up by a laboratory way by means of its own cages. Computer tomography and 3D - the printer gave the chance to create the exact copy of the necessary element.

After that studying of such technologies continued, experimenting the different directions. Whether it is boundless Additive technologies? Opportunities are how rich at it? While it precisely is not known, however is clear that else there will be many interesting opening.

toto to

to

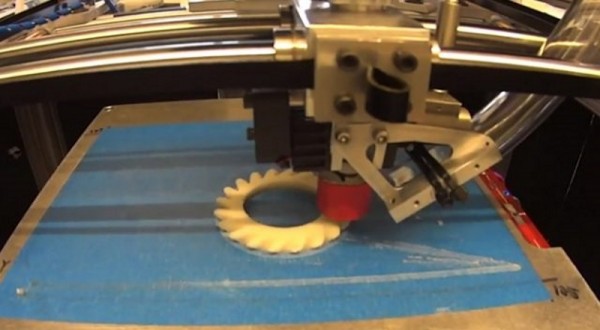

For example, not so long ago it became known of development of the fast 3D - the printer engineers of MTI. Note that the additive press is a little braked in development as to create details very long. Generally printers print something small almost an hour. However now all in a different way: the advanced technology allows to cope with an objective in only a few minutes.

Professor John Anastasios Hart and the graduate of institute Dzheymisong Guo studied factors which slow down work. It appeared that the printing head slowly moves, there is a problem with pressure which is engaged in material pushing out from a nozzle, and also melting of the last. According to Hart, at understanding of because of what it is necessary to wait hour, it was succeeded to create the new printer, having improved at it each indicator. Some internal mechanisms were changed, and also the laser that the plastic raw materials melted quicker is added.

the New device were designated by FastFFF. However, work is not finished yet. The project it becomes exact successful if it is possible to deal with distortion of a form and deterioration of details. The matter is that time the press faster, to the previous layer difficult sharply to be cooled therefore it spoils a little. However, according to engineers, they are completely sure, as it will debug. So soon, probably, development will appear in the market. The exact time is not specified yet.

Original application Additive technologies were found by other experts. The matter is that the African animals, and especially – rhinoceroses, gradually perish because of poaching. Their horns, tusks and teeth – very popular and expensive goods for which hunt, doing big harm to the African fauna.

That it to avoid

decided to develop technology the press of artificial parts of a body of animals thanks to what production becomes cheaper and production of natural trophies will stop being the favorable. Allegedly, has to it will turn out so that neither the intermediary, nor the buyer did not notice differences meanwhile what will be the copy and the original so goods become less valuable.

to

the Fake will start doing by means of special bioink. First of all will try to let out horns of a rhinoceros, and then elephant tusks, tiger teeth and scales pangolinov. The last represent pangolins who can be turned in a ball. Relatives on some features of a being – anteaters and battleships. The scales are considered medical though many physicians more than once disproved such statement. However, also pangolinov simply eat. Their meat – a popular dish at some South African people. Beings also do not live almost in bondage therefore the contents them is strongly complicated.

it is interesting to

can even build the house. For example, in February of this year there was information on the handyman from Moscow region. According to him, that there was a concrete box for the small room, 1 day is necessary only. Thus, the relief is allowed anyone, and workers it is necessary less. One observes that occurs on the computer, and the second controls that the construction material moved. Besides, work almost silent therefore you will not disturb neighbors.

to the Operator should have loaded only model in a digital format on 3D - the printer, and then to click a key of a mouse and to start printing. Supply of solution happens in an automatic mode, and the equipment scans where exactly to put ready and remembers what relief. Builders to knead a material, are not necessary. That solution did not freeze, a place of building covered with a special tent. Respectively, everything left much more simply and quicker, and the main objective is carried successfully out.